Video modal

Education

At PrimeAsia, we are passionate about empowering our customers through education. Our Leather Workshop platform offers a range of modular sessions that can be customized to explore key topics—from the fundamentals of leather manufacturing and quality testing to the intricacies of supply chain traceability and sustainability. Delivered in-person at our customers' locations worldwide, these sessions foster a collaborative learning environment where practical insights and industry knowledge are shared. Reach out to your local PrimeAsia representative to learn more about our modules and schedule an in-person educational workshop.

Leather Naturally is a leading educational platform dedicated to promoting responsible leather use. They provide brands, designers, and consumers with valuable insights into leather’s benefits, sustainability, and environmental impact. As a trusted resource, they complement our leather workshop by offering in-depth information on material performance, responsible sourcing, and industry best practices.

Leather making is both an art and a science—a journey that transforms raw hides into premium, enduring materials. In this section, we invite you to explore the meticulous processes behind each stage of production. Our video series takes you from the initial selection and preparation of hides through the detailed techniques of retanning, drying, and finishing, revealing the craftsmanship and innovation that have defined this tradition for centuries. Whether you're a seasoned artisan or simply curious about the craft, this visual guide sets the stage for a deeper appreciation of leather making.

Wet Blue Operations

Wet blue operations form the critical bridge between raw hide and finished leather. The intermediate operations are essential in ensuring the material’s durability and readiness for subsequent finishing processes, ultimately transforming wet blue into a premium quality product for diverse applications.

Crust Operations

Crust is the semi-finished stage of leather production—positioned just before the application of final treatments such as staining, oiling, and finishing. This phase is pivotal as it offers a versatile foundation to create finished leathers that meets specific criteria for texture, color, and finish.

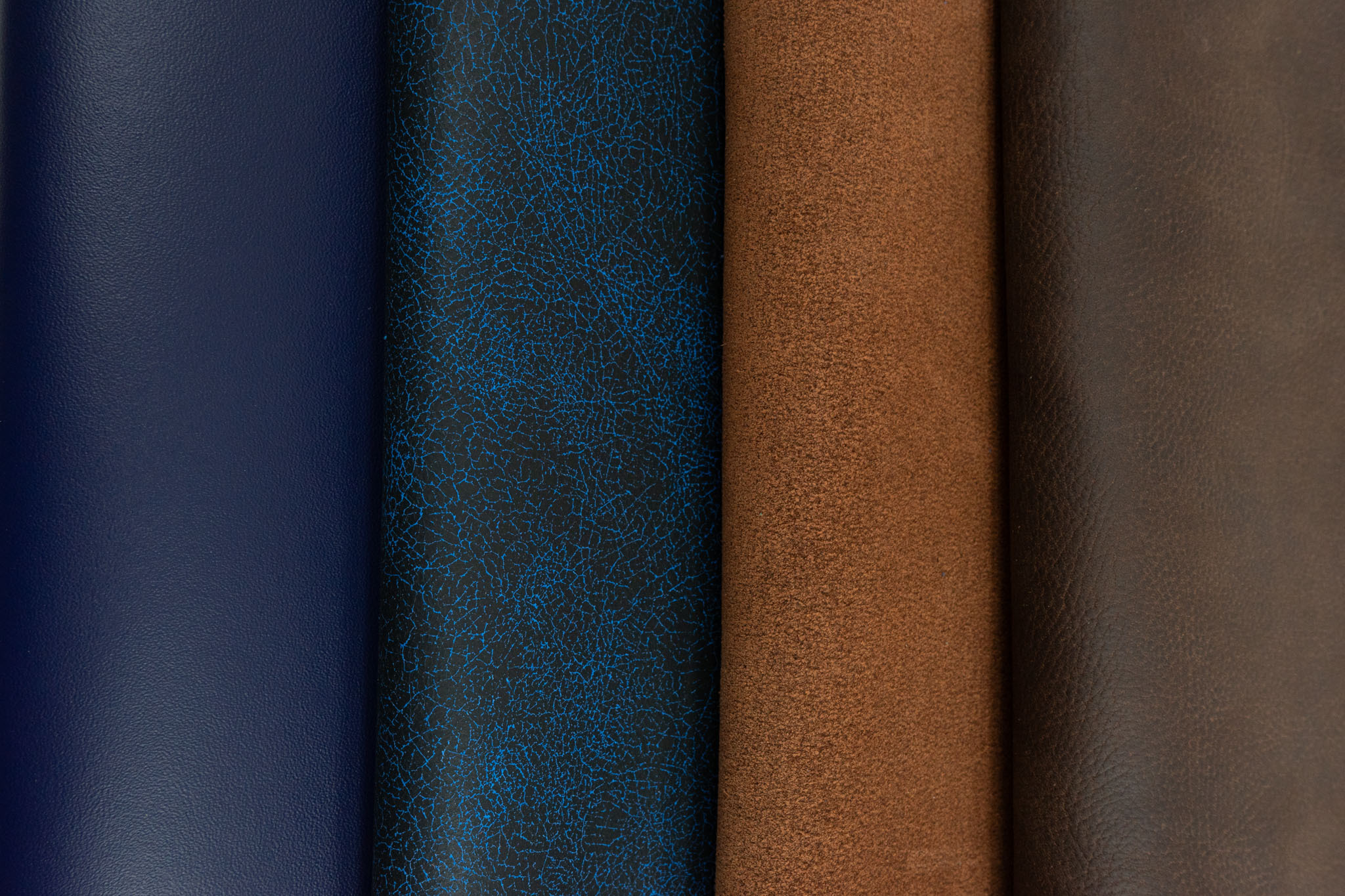

Finishing Operations

Finishing operations mark the final transformation, where art meets science to deliver a refined and durable product. In this stage, the leather receives its final enhancements—whether through color application, subtle texturing, or protective coatings—that elevate both its appearance and performance. These treatments not only highlight the natural beauty of the leather but also ensure its resilience, making it perfectly suited for a range of applications.

Operational Management